a) Standard Duty Semi Steel Body(Made out of 20 Gr cast iron having hardness of 180 to 220bhn)

b) Heavy Duty ALL STEEL BODY.(Medium cabron cast/forged steel)

c) Double slotted chucks.

d) Face plate precision chucks etc..(From 80mm to 1800mm)

Material specification:-

semi steel boy:20 Gr. cast iron having hardness of 180 to 220 bhn,

semi steel boy:20 Gr. cast iron having hardness of 180 to 220 bhn,

All steel bdoy: Medium carbon forged/cast steel

Hard Jaws: EN 353,Hardness 55 to 60 HRC gripping

All steel bdoy: Medium carbon forged/cast steel

Hard Jaws: EN 353,Hardness 55 to 60 HRC gripping

area.trreading portion will be induction annealed to avoied breakage or premacture wearing of

connecting parts.

Lead Screw, Gattoo : Medium carbon direct hardening steel suitbly toughened.

Lead Screw, Gattoo : Medium carbon direct hardening steel suitbly toughened.

Independent chucks are manufactured & tested to ISI 10612-1983.

Independent chucks are manufactured & tested to ISI 10612-1983.

All spare parts of the chucks are made to be interchangeable for easy replacement. The replacement are however, available in sets to prevent non-uniform grip in the chucks.

Selection of 4-Jaw Chucks : The size of the chuck-dependent on the capacity/size of the machine. The diameter of the chuck should be slightly less than twice the centre height of the machine.

Standard Duty Chucks :

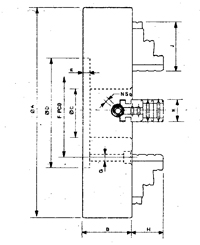

| Sl. No. |

Chuck Size |

ΦA | B | ΦC | ΦD H7 |

E | F PCD |

G | H | J | K | N Sq | Weight Kgs |

| 1 | 4" | 102 | 50.8 | 25 | 38 | 10 | 62 | M8 | 16.0 | 35 | 19.05 | 6 | 3.5 |

| 2 | 5" | 127 | 50.8 | 30 | 50 | 10 | 78 | M8 | 20.5 | 48 | 19.05 | 6 | 7.0 |

| 3 | 6" | 152 | 50.8 | 40 | 63.5 | 10 | 82.5 | M8 | 20.5 | 48 | 19.05 | 6 | 9.0 |

| 4 | 8" | 203 | 74.0 | 50.8 | 109.53 | 5.5 | 89.0 | M10 | 33.5 | 73 | 30.16 | 9 | 15.0 |

| 5 | 10" | 254 | 76.0 | 6305 | 120.65 | 8.0 | 98.4 | M10 | 33.5 | 73 | 30.16 | 9 | 19.0 |

| 6 | 12" | 305 | 87.5 | 76.2 | 152.40 | 9.5 | 130.0 | M12 | 45.0 | 98.5 | 36.0 | 12 | 34.0 |

| 7 | 14" | 355 | 90.5 | 76.2 | 177.80 | 12.7 | 146.0 | M12 | 45.0 | 98.5 | 36.0 | 12 | 46.0 |

| 8 | 16" | 406 | 93.5 | 76.2 | 177.80 | 12.7 | 146.0 | M16 | 52.0 | 120.5 | 37.7 | 12 | 58.5 |

| 9 | 18" | 457 | 93.5 | 100.0 | 200.00 | 12.7 | 171.45 | M16 | 52.0 | 120.5 | 37.7 | 12 | 70.0 |

| 10 | 20" | 508 | 109.5 | 104.7 | 241.30 | 12.7 | 203.20 | M20 | 64.0 | 144.5 | 42.79 | 12 | 95.0 |

| 11 | 22" | 559 | 109.5 | 104.7 | 241.30 | 12.7 | 203.20 | M20 | 64.0 | 144.5 | 42.79 | 12 | 110.0 |

| 12 | 24" | 610 | 116.0 | 139.7 | 304.80 | 19.05 | 260.35 | M20 | 64.0 | 144.5 | 42.79 | 12 | 142.0 |

| 13 | 26" | 660 | 116.0 | 139.7 | 304.80 | 19.05 | 260.35 | M20 | 64.0 | 144.5 | 42.79 | 12 | 160.0 |

| 14 | 30" | 762 | 127.0 | 152.4 | 381.0 | 19.05 | 304.8 | 8M20 | 81.0 | 174.5 | 53.97 | 16 | 240.0 |

| 15 | 32" | 812 | 127.0 | 152.4 | 381.0 | 19.05 | 304.8 | 8M20 | 81.0 | 174.5 | 53.97 | 16 | 290.0 |

| 16 | 36" | 915 | 127.0 | 177.8 | 450.85 | 19.05 | 355.6 | 8M20 | 81.0 | 174.5 | 53.97 | 16 | 380.0 |

The diameter of the Chuck should be grater than the diameter of the job to be held. Also, when a job is held in a Chuck all the jaws should be inside the chuck body.

The diameter of the Chuck should be grater than the diameter of the job to be held. Also, when a job is held in a Chuck all the jaws should be inside the chuck body.

The chucks require a backplate to suit the spindle of the machine. The diameter of the backplate should be equal to the recess in the chuck body.

The chucks require a backplate to suit the spindle of the machine. The diameter of the backplate should be equal to the recess in the chuck body.